Product overview

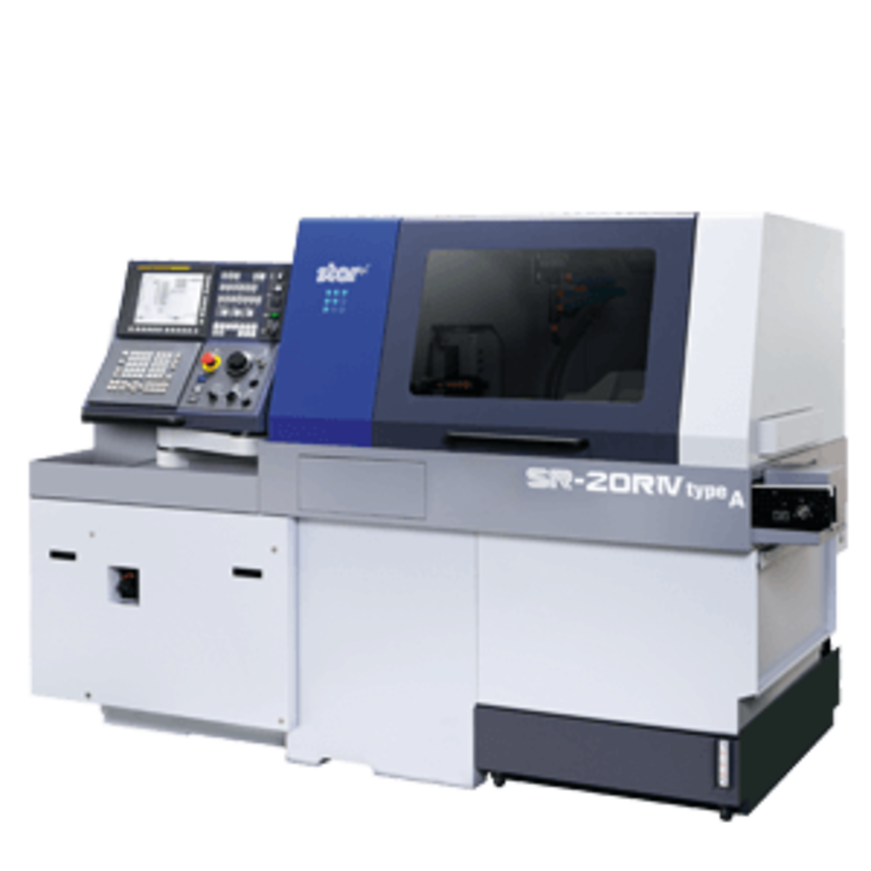

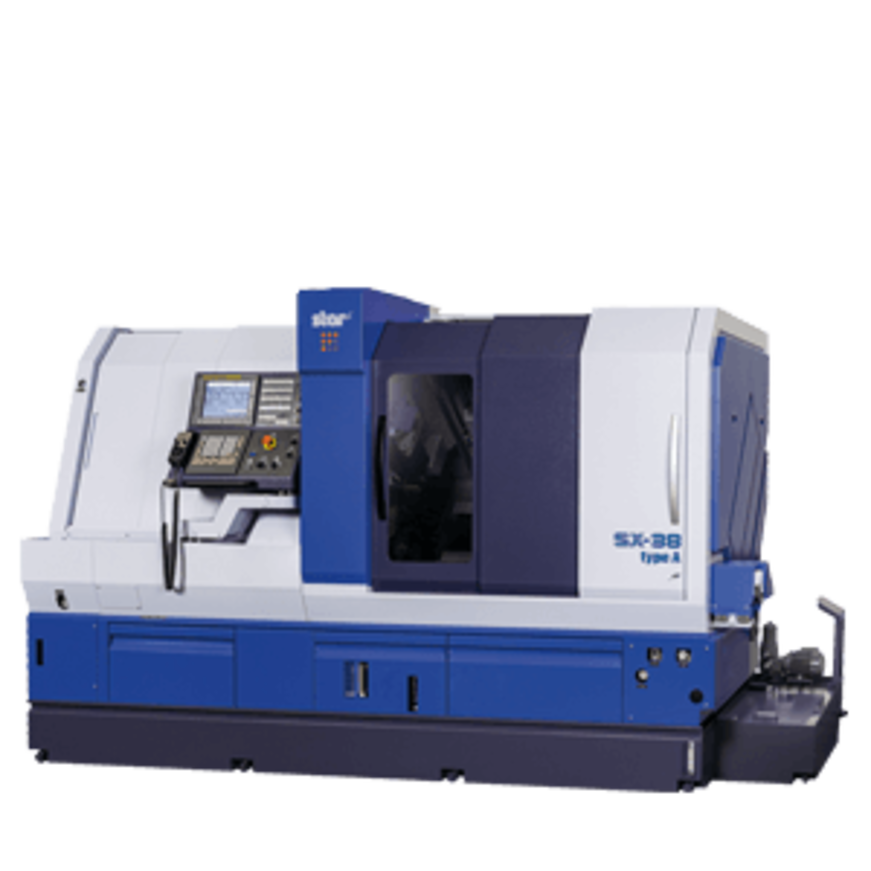

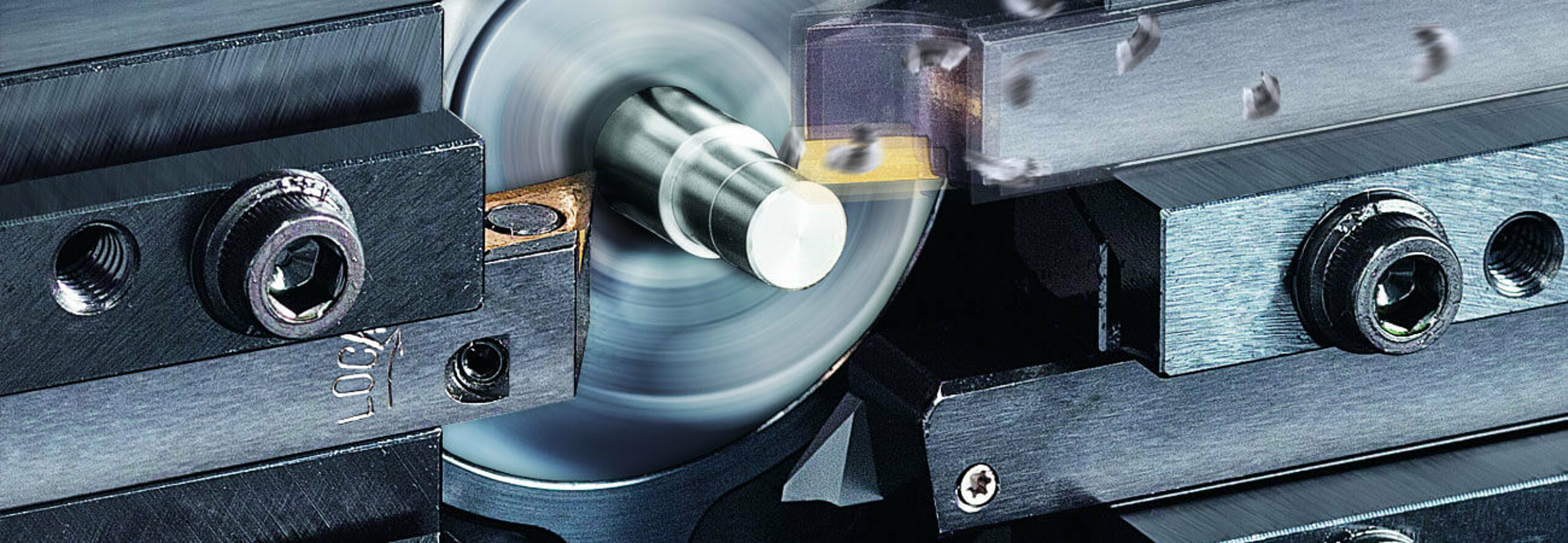

CNC automatic lathes

Job vacancies

Current apprenticeship vacancies

Any questions?

+49 (7082) 7920-0

Infostar

Customer magazine

With articles on new products, projects, success stories and much more, in our annual customer magazine you can inform yourself about exciting news from the star* company. We wish you lots of reading fun.

STAR Micronics GmbH

15,000

star* CNC automatic lathes delivered in Europe

1979

Founded

7

Locations worldwide

24 months guarantee 1

without limitations

Guarantee extended to 24 months

– without operating hours limitation

In the meantime, the reliability and long life of our star* CNC automatic lathes has become legendary. As we are convinced about the high quality of our products, in future we will grant you a warranty of 24 months on our star* CNC automatic lathes1.

This regardless of whether you produce with two or three shifts on our machines.

1 Except for wear parts.

HFT Flyer

Your advantages

with star Micronics

- Training

STAR Micronics GmbH offers special training sessions for machine operators. You as customer can decide whether to have the training in our company or on your premises. The training is naturally exclusively for your personnel and specifically designed for your range of parts. - High pressure unit

The machine can be retrofitted with high pressure units from 50 to 300 bar. In addition, other developments are available to you, such as programmable pressure control or complete filtration. - Cooling lubricants

The machine can be run with oil or with aqueous emulsions. However, we recommend the use of oil as this is far more beneficial to the longevity of the machine. - Bar feeder

All commonly available bar feeders (FMB/IEMCA/LNS) can be used with the machine. The software interface is included in the machine as standard.

- Chip conveyor

The machine can be fitted with a chip conveyor or a chip flushing system. - Peripherals

Peripheral components such as parts separators, purchased coolant units (oil/emulsion), coolant filters, fire protection systems and TPM (tool process monitoring) can also be offered. A retrofit of peripheral components is always possible. - Service

SSC star* Service Connect as 24/7 customer portal and online connectivity for your machines, tickets and service calls. A current overview can be called up at any time. In addition, you have access to the star* knowledge database

Your advantages

with star Micronics

- Training

STAR Micronics GmbH offers special training sessions for machine operators. You as customer can decide whether to have the training in our company or on your premises. The training is naturally exclusively for your personnel and specifically designed for your range of parts. - High pressure unit

The machine can be retrofitted with high pressure units from 50 to 300 bar. In addition, other developments are available to you, such as programmable pressure control or complete filtration. - Cooling lubricants

The machine can be run with oil or with aqueous emulsions. However, we recommend the use of oil as this is far more beneficial to the longevity of the machine. - Bar feeder

All commonly available bar feeders (FMB/IEMCA/LNS) can be used with the machine. The software interface is included in the machine as standard.

- Chip conveyor

The machine can be fitted with a chip conveyor or a chip flushing system. - Peripherals

Peripheral components such as parts separators, purchased coolant units (oil/emulsion), coolant filters, fire protection systems and TPM (tool process monitoring) can also be offered. A retrofit of peripheral components is always possible. - Service

SSC star* Service Connect as 24/7 customer portal and online connectivity for your machines, tickets and service calls. A current overview can be called up at any time. In addition, you have access to the star* knowledge database

- bar feeding: bar feeder

- chip disposal: chip conveyor

- long parts ejector

- beacon: acc. to customer requirements

- high pressure unit: 50 to 300 bar

- fire protection: small fire extinguishing system

- complete filtration coolant

- Tools in the internet at www.star-tools.eu