Step-Cycle-Pro

A pioneering development in chip control

Building on the success achieved by HFT, we’ve taken no time in creating another chip-breaking innovation. To keep this complex process as simple as possible, only the required target chip length needs to be entered.

Advantages

- Prevents chip problems and significantly reduces rejects

- Uniform surface finish

- Cycle time easy to control

- Reduces machine stoppages

- Shortens retooling time

- Easy retrofit at an inexpensive price

- Simple handling with G-code

SCP (Step-Cycle-Pro) is the most recent breakthrough in tackling the challenges that are presented by the awkward chip lengths produced by machining long-chipping materials such as aluminium, stainless steel, copper and plastics.

Chipping problems?

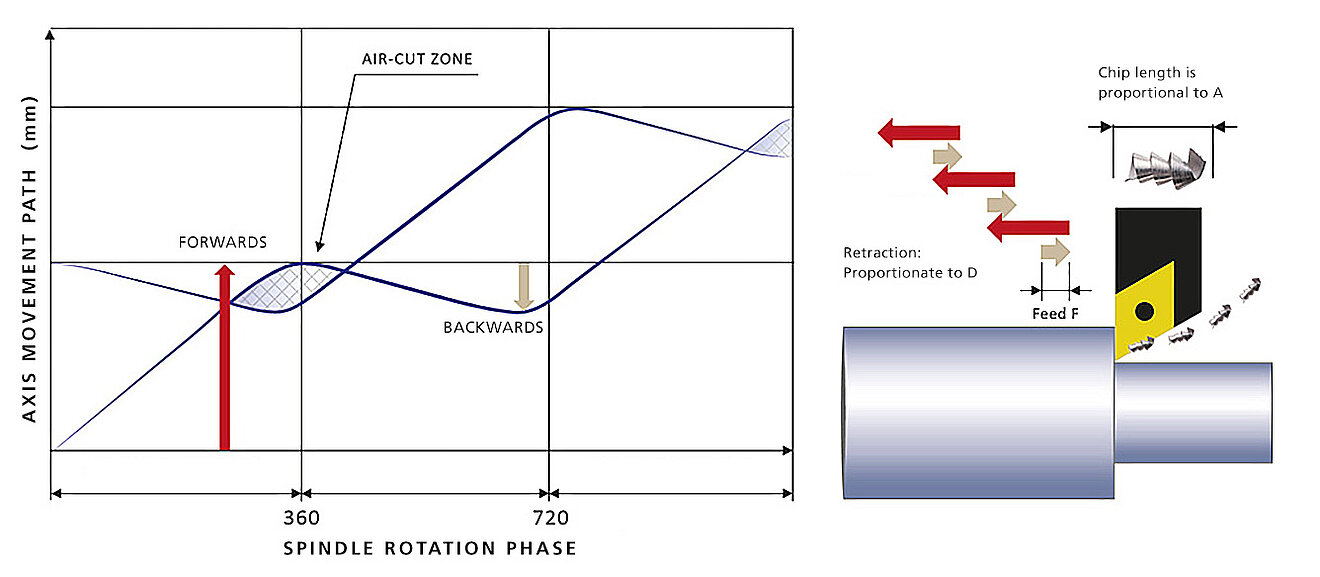

With its oscillating axis motion, Step-Cycle-Pro offers several advantages in relation to chip control and tool life. In terms of chip control, an ‘air cut’ can be defined to form the chip. This air cut is achieved by a controlled interpolation between a spindle and axis. In addition, thermal load on the tool tip is also reduced during operation. This effectively prevents damage to the tool coating. SCP can be used on the main and sub-spindle without any restrictions.

Step-Cycle-Pro was developed for a wide range of machining types, such as turning, drilling, facing and pricking. SCP offers a database with recommendations, which the machine operator can use to select the ideal program conditions and chip length. The technology requires no special expertise to use and can be easily activated or deactivated with a one-line G-code command.

As is typical for other brands of CNC turning machines, a slight increase in cycle time is to be expected with the use of similar oscillation techniques. The advanced system developed by star* can adjust the actual feed speed automatically when the function is activated. To ensure that the cycle time remains unchanged, the cut data is then adjusted accordingly.

ASK FOR A quote TODAY

Please let us know which type of machine you want.

We will give you a quote for this machine’s default configuration.

Product overview

CNC automatic lathes

Any questions?

+49 (7082) 7920-0